How to Choose Industrial Plug

DATE:2021-07-23

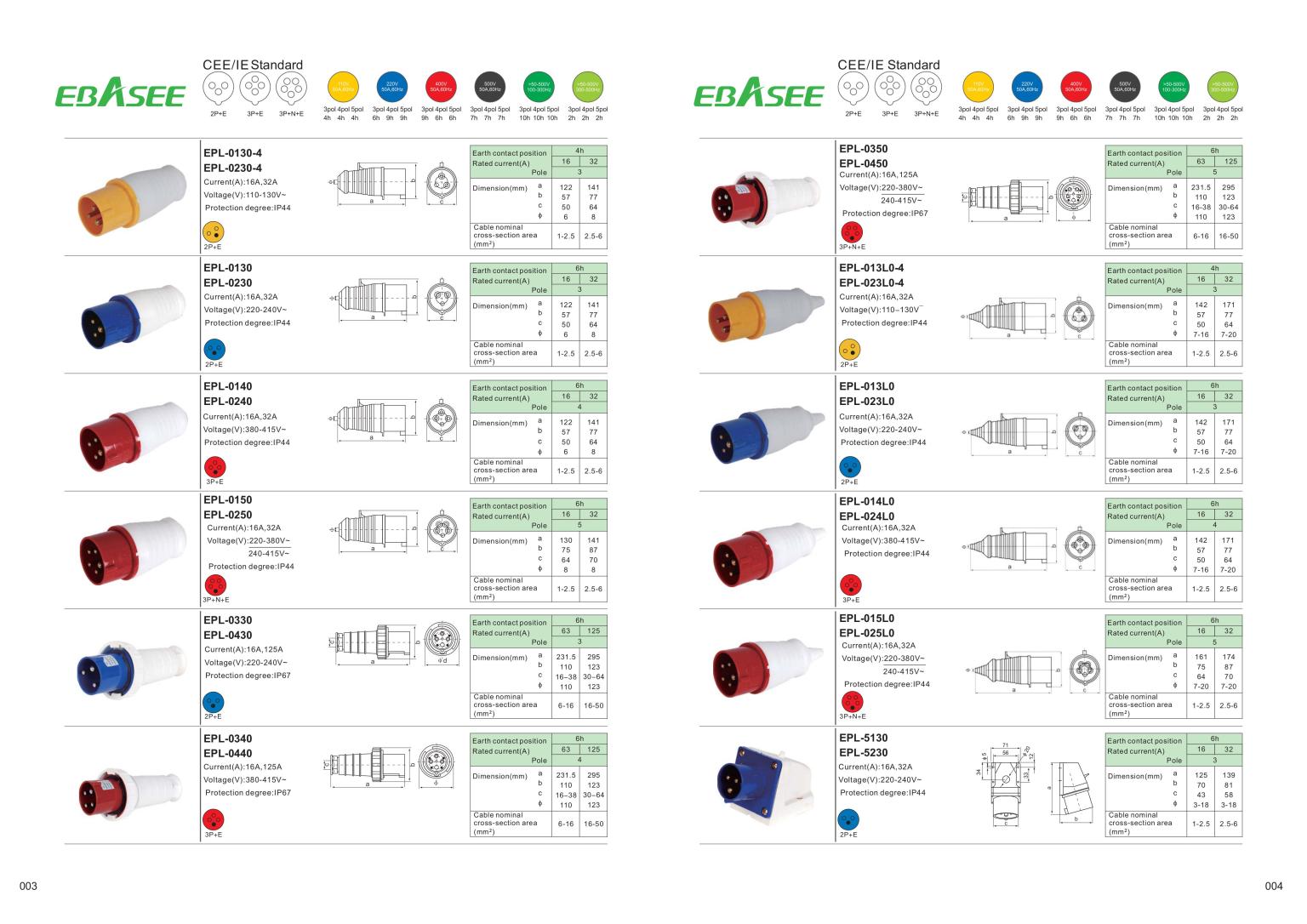

Industrial plugs are generally divided into 3 cores, 4 cores, 5 cores, etc. The current is generally divided into 16A, 32A, 63A, 125A, 250A, 420A, etc., and the protection level can be divided into IP44 and IP67. Material: nylon PA66

How to choose the right industrial plug?

1. How to choose a suitable connector plug? First of all, we need to consider what the plug needs to be connected to and where to use the connector plug. This issue requires very careful consideration. It needs to consider whether it is used indoors or outdoors. The type of industrial plug will determine which terminal to use. Technical reference.

2. Electrical requirements When selecting electrical connectors, the electrical requirements of the product must be considered. What are the voltage and current requirements of the product, and whether the connector can be used in such electrical applications? These issues about electrical requirements need to be considered. In addition, we also need to consider some other electrical conditions: resistance, allowable resistance change, millivolt drop, maximum current value, maximum voltage value, inrush current value, characteristic impedance, VSWR (voltage standing wave ratio), plug Pull loss and EMI shielding efficiency.

3. Environmental requirements. Temperature, humidity and other environmental conditions are determined by the location of the electrical connector, so the location and expected environment should be considered. What is the shelf life and information of other relevant storage conditions. The description of the environment should also include requirements for shock and vibration, including requirements from shipping, and production environmental conditions such as welding temperature and welding cycle duration. The connector manufacturer states that the area where the highest temperature is generated is around the convergent continuous current guided by the connector.

The scope and characteristics of industrial plugs and sockets

Applicable to various indoor and outdoor places such as industry, agriculture, chemical industry, food, airport, dock, ship, metallurgy, power plant, construction and tertiary industry;

Structural characteristics of industrial sockets:

-According to the installation method: mobile, surface-mounted, and concealed;

-According to whether the socket is equipped with a protective device: without a protective device, with a fuse, and with a miniature circuit breaker;

-According to whether the socket is equipped with interlocking device: without interlocking, with mechanical interlocking, and with electrical interlocking;

-According to whether the socket is equipped with a safety transformer: without transformer, with transformer;

Uses and characteristics

1. Industrial plugs and sockets in our country

Industrial plugs, sockets and couplers are mainly divided into four categories: plugs, sockets, connectors and appliance input sockets, generally collectively referred to as industrial plugs. As shown below:

The earliest relevant standard in my country was promulgated in 1989, "Industrial Plugs, Sockets and Couplers" GB/T 11918~11919-1989. At this time, there was no industrial plugs and sockets produced in China.

Then, here comes the problem. We can't avoid using imported equipment, right? What should I do if these devices are not available for industrial plugs and sockets? Two words: import. At that time, importing was a very troublesome thing, and time and money could not be consumed. Therefore, sometimes in order to control costs, smart engineers simply cut off the plug and connect it directly to the power switch.

Until the mid-1990s, through the introduction of joint ventures, the domestic mass production of various industrial plugs and sockets gradually.

Second, the characteristics of industrial plugs and sockets

1. Safe and reliable

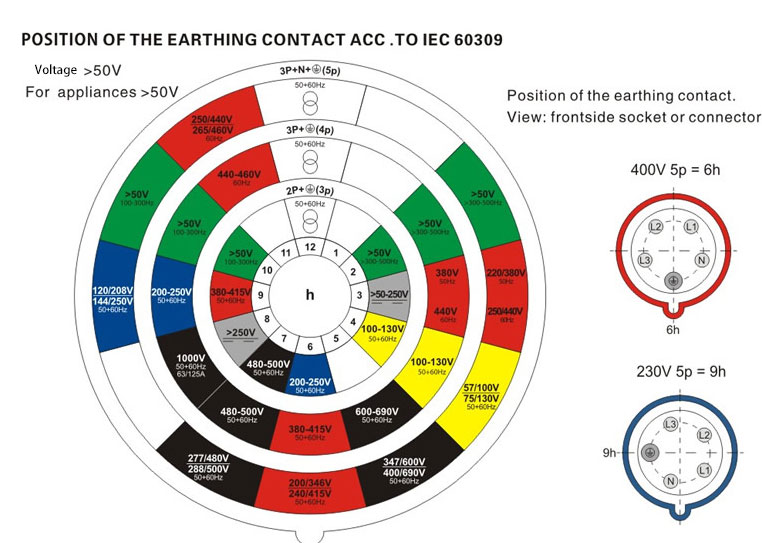

(1) This type of product uses the color of the shell to indicate the rated voltage, such as blue for 220V, red for 380V, which is clear at a glance, easy to distinguish, and you can't make a mistake.

(2) The diameter, number of poles, and grounding contact positions of products of different specifications are different. Only the same specifications can be plugged in to prevent misplugging.

(3) There is protection against electric shock. The grounding pole insert sleeve in the socket is longer than the phase pole and the neutral pole insert sleeve, which ensures that the ground pole is connected before the phase pole is connected when the plug is inserted, and the ground pole is finally separated when the plug is pulled out, which is very safe to use.

(4) High degree of protection. There are IP44 splash-proof type, IP67 anti-immersion type and so on. Not only the human body cannot touch the live parts, but it can also be used under different environmental conditions to ensure safety.

(5) An elastic band is added to the insert sleeve. Ensure close contact, good conductivity and longer service life after the plug is inserted.

(6) There is a holding device, which makes the plug and socket clamp each other to prevent falling off after being inserted, and the reliability is greatly improved.

(7) There is a cable clamping device, which can clamp the cable sheath so that the fixing wood will be pulled off, which is safe to use.

2. durable

(1) Good mechanical properties. The product shell is made of high-quality engineering plastic, which has high strength, impact resistance, and is not afraid of falling or stepping on it. The rubber and plastics used have anti-aging properties, and can be used not only indoors but also outdoors, and are durable.

(2) Heat and flame resistance. The shell and internal insulating parts have heat resistance, the temperature can reach (100±5)℃, and the important parts can withstand (125±5)℃; and they are flame retardant.

(3) It is more resistant to plug and use. Such as a product with a rated current of 16A, the number of normal plug-in operation cycles is more than 5000 times.

(4) The temperature rise test of conductive contact parts (plug, socket) does not exceed 50K, suitable for long-term use.

3. Strong versatility

The product adopts the GB/T 11918~11919-2001 standard, which is equivalent to the IEC 60309-1, 2 standard and is fully in line with international standards. Therefore, this type of product is commonly used domestically and internationally. At the same time, it has a wide variety of specifications and can meet various occasions and uses.

These characteristics of industrial plugs and sockets make it highly safe, reliable and international. Therefore, it has gradually received attention in the country. Through more than ten years of continuous promotion and application, industrial plugs and sockets have entered various industries, such as electricity, construction, ports, machinery industries and modern large-scale buildings. Manufacturers have also grown from the first few to dozens of now. At the same time, with the development of science and technology, industrial plugs and sockets are constantly innovating, and various quick installation technologies have been applied to plugs and sockets to make them more convenient.

Instructions

Poor quality of plugs, sockets and converters is an important cause of electrical fires. The quality problems of small plugs, sockets and converters will pose a serious hazard to the personal and property safety of consumers. Therefore, when consumers buy plugs, sockets, converters, and switches, they should focus on the safety of the products, and the following performance indicators affect their safety:

The sign is an important basis for instructing people to install, use and maintain correctly, and is an extremely important safety standard content to ensure the safety of personal and property. Plug and socket products should be marked with the rated current, rated voltage, power source, etc. in an obvious position. In addition, converters (converters refer to mobile electrical accessories that have only one plug part and one or more socket parts combined) products must use the "MAX (or maximum)" symbol to mark the rated current/or power. To guide users to avoid overloading. Signs or symbols should be durable and legible. Do not use silk screen and paper stickers that can be easily erased

Rated value

Rated value is the most basic electrical interchange coordination parameter to ensure the normal, safe, and coordinated use of plugs, sockets, converters and connected electrical appliances. For example: the rated current of the converter shall not be greater than the rated value of the plug part. Otherwise, it may cause danger when the user selects electrical appliances according to the rated current of the socket, the plug is overcurrent and generates heat; the minimum rating of the converter with fuse and overload protector should be equal to the mark on the fuse and overload protector The rating. Otherwise, product damage may occur.

size

Size is an important technical requirement related to whether plugs, sockets and converters can be used safely, and whether they meet general interchangeability requirements to avoid mis-insertion. Unqualified size will affect the user's use or cause hidden dangers such as poor contact and mis-insertion, ranging from damage to the equipment, and serious to fire and electric shock accidents.

Protection against electric shock

Anti-electric shock protection is a key safety index to ensure that plugs, sockets and converters will not cause electric shock accidents to users and others under normal use, and even some accidents. When the plug is fully or partially inserted into the socket, the live part of the plug should not be touched; any pin of the plug should not be able to be inserted into the live socket of the socket when the other pins are in the reachable state. Plug sockets and converters with protective doors should be able to prevent single poles or probes from being inserted.

structure

The plug sleeve assembly of the socket should have enough elasticity to ensure sufficient contact pressure on the plug pin. The insert sleeve should be corrosion-resistant and wear-resistant to ensure good contact between the plug and the socket; the plug of the plug should be locked and cannot be rotated, otherwise it will affect the insertion performance and cause unsafe factors; the converter has a flexible cord fixing device to ensure The flexible cord is fixed and can withstand normal tension and torsion; when the plug and socket are inserted, the mating surface should be basically tight to prevent electric shock accidents.

power cable

The power cord should have enough cross-sectional area to ensure that the power cord will not heat up and cause insulation damage, causing short circuits, fires, leakage, and accidents. For example, the cross-sectional area of the power cord of a common 250V, 10A converter should be greater than or equal to 0.75mm2.

Mechanical strength

Plugs and sockets should have sufficient mechanical strength to withstand various mechanical stresses caused by drops, impacts, squeezing, etc. during installation and use; sockets with protective doors should be able to prevent unipolar insertion.

Heat and flame resistant

High temperature has a great influence on the various properties of insulating materials. Under high temperature conditions, the structure and characteristics of insulating materials will undergo essential changes. This change determines the reliability of the material. Some materials will gradually become soft at high temperatures. The mechanical strength decreases, which will affect the quality of the plug and socket and the safety in use. In addition, the insulating material of the plug and socket should have a certain flame-retardant performance. Otherwise, the product will be out of control if it catches fire during use.